Tarillo Vue

We've changed our name. We're now Structura View.

About Structura View

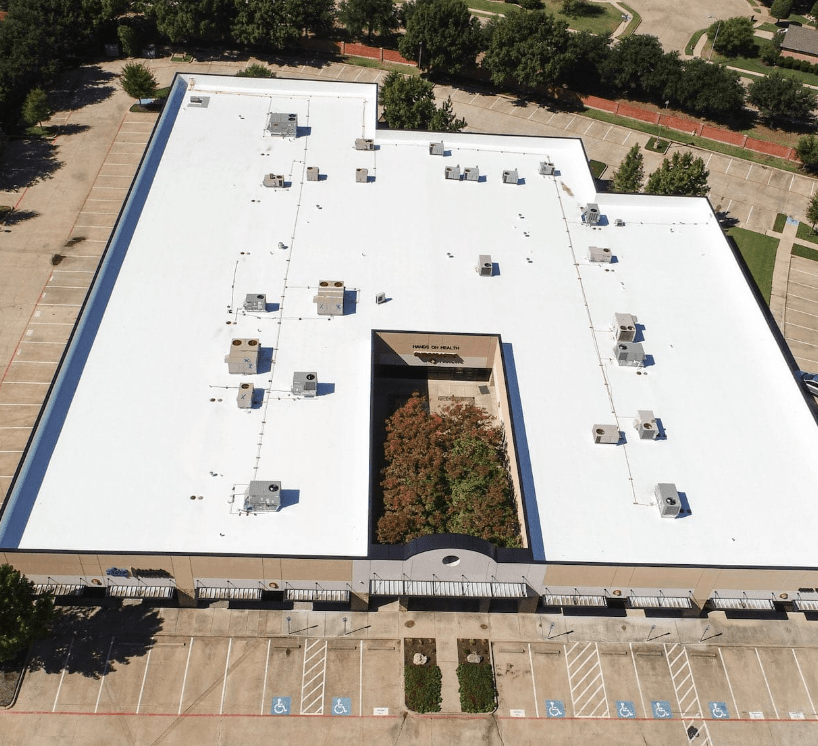

Structura View is a full-service roof consulting agency helping commercial property owners and other industry professionals manage and extend the life of their buildings. We provide drone inspections, moisture testing, reporting, consulting, and more.

Our History

2015

Launch of Tarillo Vue Creative Drone Photography

Full service creative drone photography service is launched in Dallas, Texas.

2017

Thermal Imaging Added

to Service Offerings

Investigations of commercial roofing systems are added to Tarillo Vue services.

2018

Service Regions Expanded

Tarillo Vue services expand to North Pacific,

Southeast, and Midwest.

2020

On-Roof Moisture

Mapping Validation

Moisture mapping is added to validate thermal image maps of roofs.

2021

Consulting &

Quality Assurance Offered

Providing finish product inspections

and consulting services.

2023

Then Came Structura View

Structura View rebrands as a full service roof consulting agency.

View our expanded capabilities and clients: